Phone:

(701)814-6992

Physical address:

6296 Donnelly Plaza

Ratkeville, Bahamas.

Unlock the five critical secrets behind engine rotation direction. This fundamental aspect of mechanics influences everything from performance to repair costs. Understanding it is crucial for any car owner or enthusiast. We will demystify the standard practices and explore the fascinating exceptions. Get ready for a deep dive into the spinning heart of your vehicle. This guide will transform how you see engine operation forever.

Engine rotation direction is the invisible force governing your vehicle’s soul. It dictates how power flows from the combustion chamber to the wheels. This single characteristic impacts component longevity and driving dynamics. Ignoring it can lead to costly repairs and subpar performance.

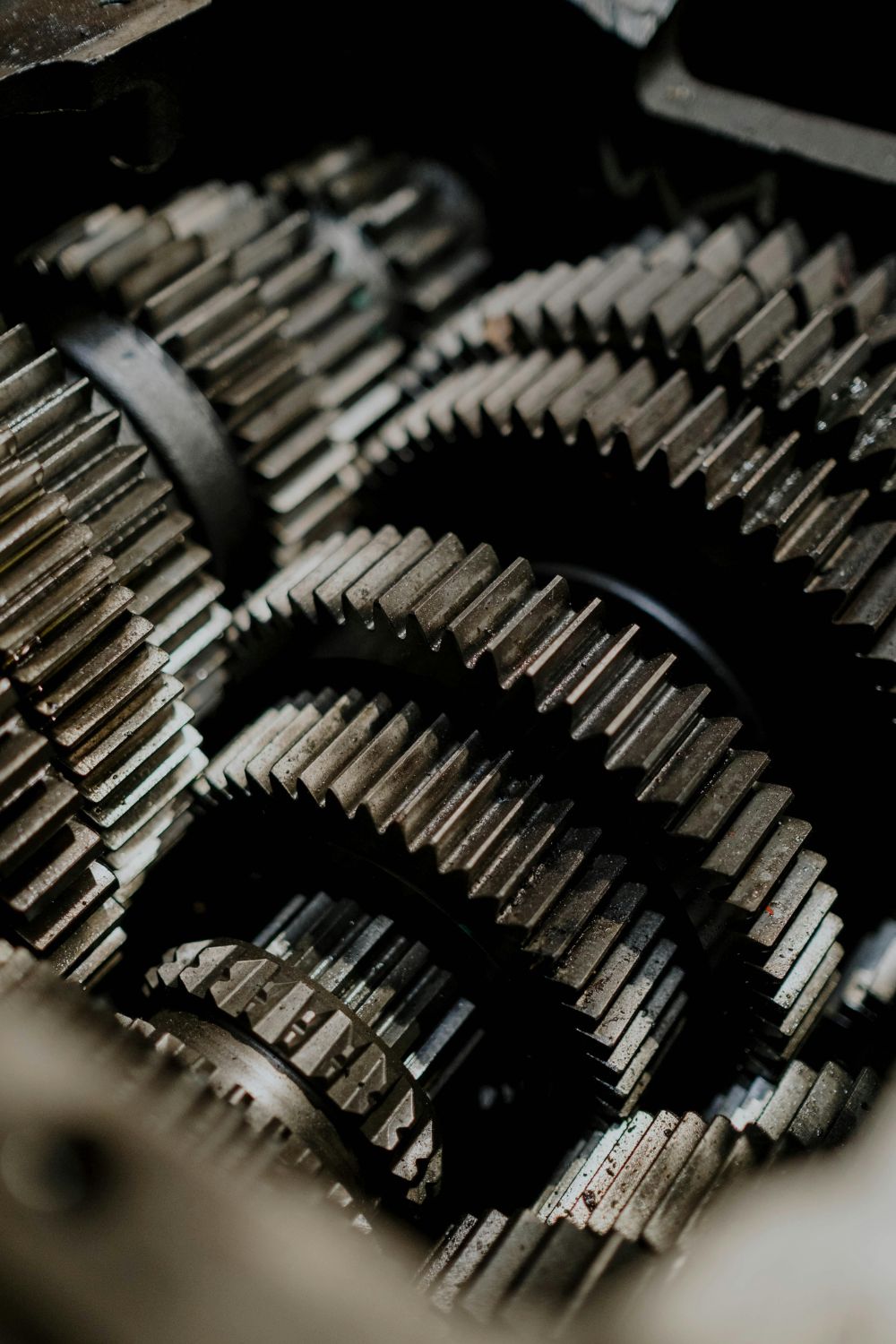

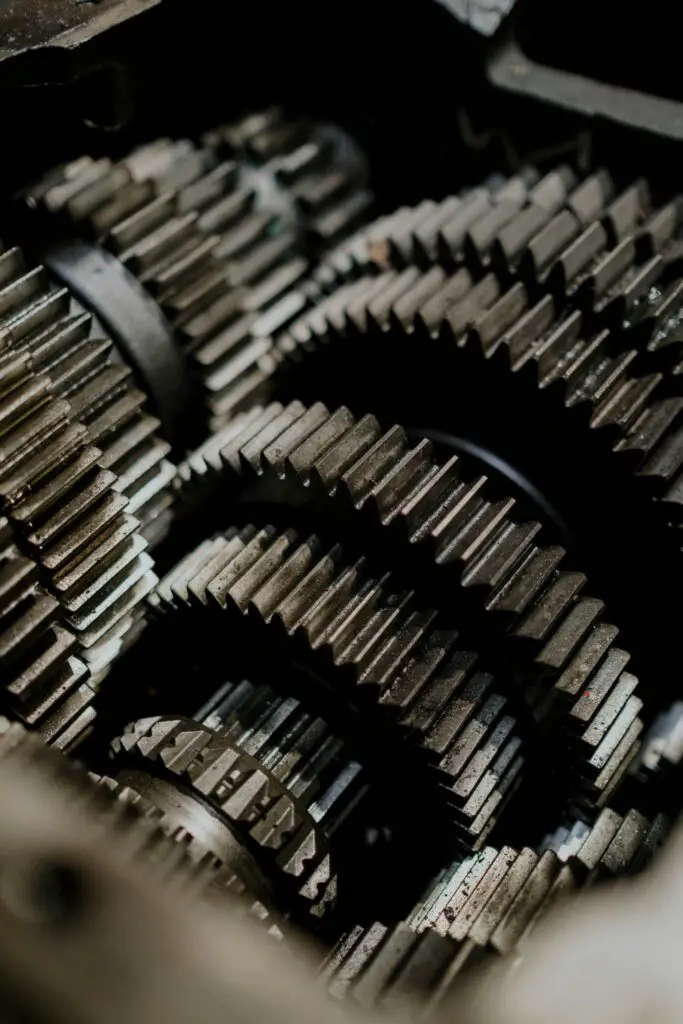

The crankshaft’s spin dictates the entire engine’s rhythm. Components like the camshaft, oil pump, and water pump are designed for a specific rotation. Reversing this direction can starve the engine of oil and coolant. This precise synchronization is vital for engine health and longevity.

Rotation direction creates a subtle gyroscopic effect in the engine. This can influence how a vehicle handles, especially during hard acceleration. High-performance cars sometimes leverage this for better cornering stability. The direction of power pulse also affects traction and drivetrain design.

Standardization drastically reduces costs and simplifies repairs. Manufacturers design thousands of parts for one primary rotation direction. This creates a global ecosystem of compatible components and tools. Deviating from this standard would make every engine a custom project.

The choice of clockwise rotation was not a random decision. It stems from the mechanical clocks and early industrial machinery of the 19th century. Engineers naturally adopted the familiar clockwise motion for new inventions. This historical precedent created a powerful inertia in engine design.

As the automotive industry exploded, standardization became essential. The Society of Automotive Engineers (SAE) established clockwise as the standard viewed from the rear. This allowed parts suppliers to mass-produce compatible components. It ensured a mechanic in any garage could work on most engines.

Most engines follow the clockwise standard, but exceptions exist. The direction is always described from a specific reference point. This is typically the rear of the engine, looking toward the front of the car. Understanding this perspective is key to avoiding confusion.

Clockwise engines represent over 95% of all automotive engines on the road. They are designed with right-hand-threaded fasteners that naturally tighten under operation. Their accessory drives, like the alternator and power steering pump, are configured for this spin. This design offers unparalleled parts availability and service knowledge.

Counterclockwise engines are specialized tools for specific applications. Many marine engines rotate counterclockwise to directly drive counter-rotating propellers. Some motorcycles and older aircraft engines also use this configuration. They often require left-hand-threaded fasteners on certain components.

Virtually all mainstream automotive engines rotate clockwise. This includes inline-four, V6, and V8 configurations from most manufacturers. Diesel engines in trucks and heavy equipment also follow this convention. The sheer volume makes this the default for the industry.

Several notable engines defy the clockwise standard. The classic Volkswagen air-cooled engine, found in the Beetle and Bus, is a famous example. Many outboard boat motors are designed to spin counterclockwise. Certain Harley-Davidson motorcycle engines also reverse the typical rotation.

Three primary factors lock in an engine’s rotation direction. The engine’s mechanical design is the most fundamental determinant. The vehicle’s application and packaging constraints also play a huge role. Finally, manufacturing legacy and tradition can dictate the chosen direction.

The engine’s core architecture dictates its natural rotation. The geometry of the crankshaft throws and connecting rods is set in one direction. The camshaft drive gear teeth are cut to mesh for a specific rotation. The oil pump is also a positive displacement device that only works one way.

A vehicle’s purpose can override standardization. Boats often use twin counter-rotating engines for straight-line stability. Front-wheel-drive transverse engines are flipped left-or-right in the chassis. This means even engines from the same family can spin differently.

Many misconceptions surround this technical topic. People often overstate the performance impact of rotation direction. Others believe the direction is arbitrary and can be easily changed. We will dismantle these myths with clear, factual explanations.

Clockwise rotation is not superior; it is simply more convenient. There is no inherent efficiency or power advantage to the direction itself. Counterclockwise engines can be just as powerful and reliable. The “superiority” comes from part availability and mechanical familiarity.

While a minority, counterclockwise engines are far from rare. Millions of Volkswagen Beetles and Buses were produced with reverse rotation. The global marine industry relies heavily on counter-rotating engines. Many industrial and agricultural machines also use them.

Choosing the standard rotation offers clear benefits and some drawbacks. The advantages heavily favor mass production and consumer repair. The disadvantages are mainly felt in specialized applications. For most users, the benefits overwhelmingly outweigh the limitations.

The benefits of following the standard are immense. You will never struggle to find a mechanic who understands your engine. Replacement parts are available everywhere, often at low cost. The collective knowledge base for troubleshooting is virtually unlimited.

The main drawback is a lack of design flexibility. Engineers must work around the standard, which can create packaging issues. In certain applications, like marine twins, a dedicated counter-rotating engine design. This can increase complexity for manufacturers.

Installing an engine with incorrect rotation has catastrophic consequences. The issues are not subtle and will manifest almost immediately. This can happen when swapping engines or misassembling internal components. The results are always severe and expensive to fix.

The entire valvetrain will be completely out of sync. Pistons will collide with valves, bending them instantly. The timing system will be unable to function correctly. The engine will not run and will be severely damaged if forced.

Lubrication systems will fail immediately. The oil pump will not generate pressure, starving bearings of oil. All rotating components will experience extreme friction and heat. This leads to rapid, total engine seizure within minutes.

A suddenly seizing engine can lock the drivetrain. This is an extreme safety hazard, especially at high speed. Flying metal shrapnel from failing components is another risk. Fire from spilled fuel and oil is also a distinct possibility.

Identifying your engine’s rotation is a straightforward process. You can use simple observational techniques or specialized tools. Knowing the engine model is often the fastest path to an answer. We will cover all the effective methods for confirmation.

The standard reference point is the flywheel end of the engine. Stand at the back of the engine, looking toward the front pulley. Observe which way the crankshaft pulley turns when the engine runs. Clockwise means the top of the pulley moves to your right.

A simple strobe timing light can show rotation while the engine runs. Non-contact phototachometers can also detect direction from pulley movement. For a non-running engine, a mechanic’s borescope can inspect piston movement. Always confirm with the service manual for absolute certainty.

Final Thought

Mastering engine rotation direction is a key step in automotive knowledge. This fundamental characteristic shapes design, performance, and repair. While clockwise is the overwhelming standard, brilliant exceptions prove the rule. Always confirm your engine’s rotation before any major work. Use this guide to confidently understand and identify the spin within your machine.

Historical standardization and manufacturing efficiency dictate it. Early industrial machinery established the clockwise convention. The SAE later cemented it as an industry standard. This simplifies production and repair for virtually all vehicles.

It primarily influences vehicle handling through gyroscopic precession. A clockwise engine resists turning left differently from turning right. In high-performance applications, this can be tuned for balance. It also directly determines the drivetrain layout and gear design.

It is possible, but requires extensive and complex modifications. You would need a custom camshaft, a different oil pump, and a specialized crankshaft. For most applications, it is far more practical to simply use a different engine. The cost and effort are seldom justified.

No, several notable exceptions exist throughout automotive history. The classic Volkswagen air-cooled engine is the most famous counterexample. Some older British motorcycles and cars also used reverse rotation. Always verify the specific engine model to be certain.

No, the direction itself has no measurable effect on fuel economy. Efficiency is determined by combustion efficiency, friction, and weight. A well-designed counterclockwise engine can be just as efficient as a clockwise one. The impact is on design, not fundamental thermodynamics.

The only fix is to correct the rotation direction immediately. This typically involves replacing the incorrectly configured engine. If damage has occurred, a complete rebuild with correct parts is necessary. Always diagnose the root cause, like a wrong engine swap, to prevent recurrence.