Phone:

(701)814-6992

Physical address:

6296 Donnelly Plaza

Ratkeville, Bahamas.

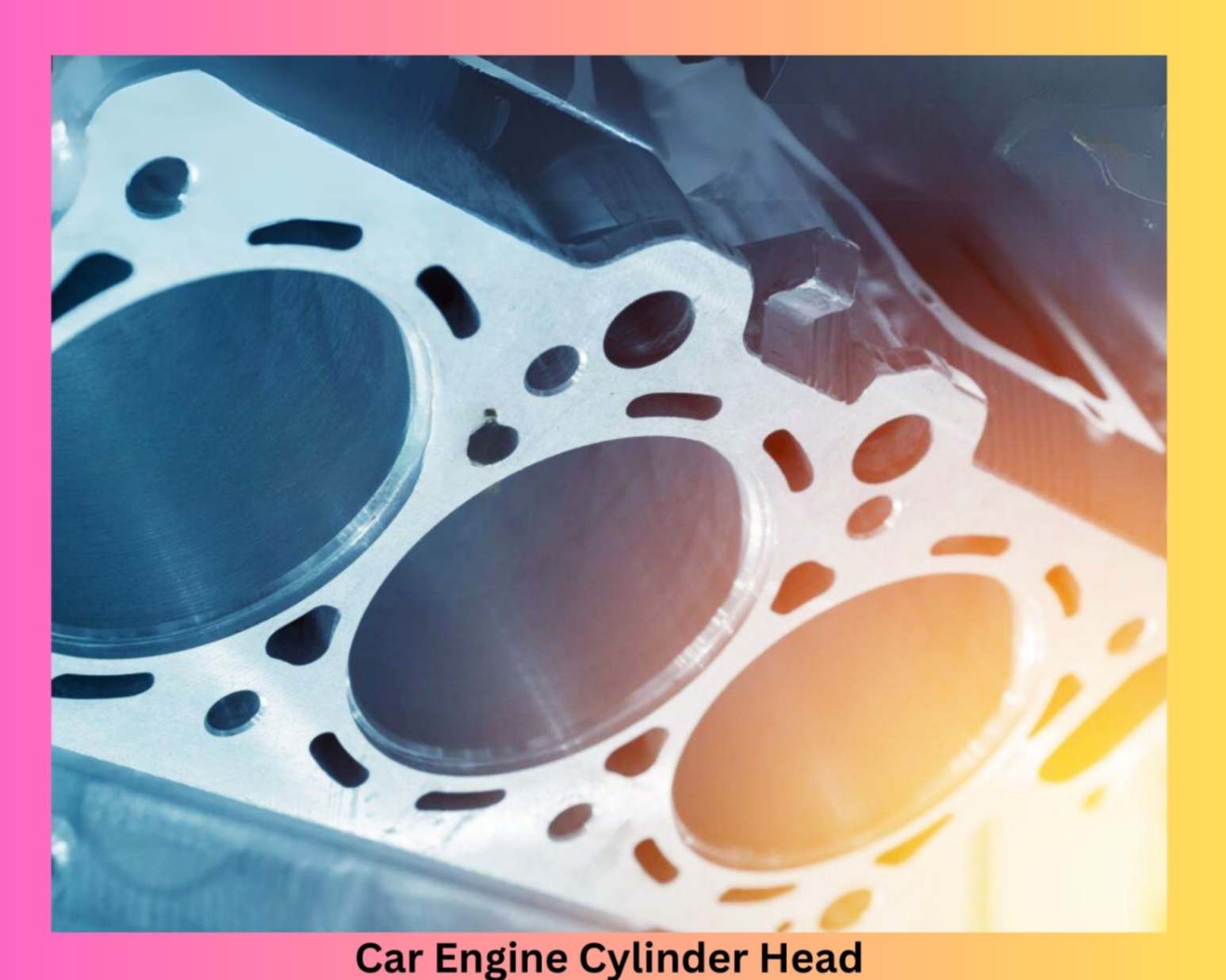

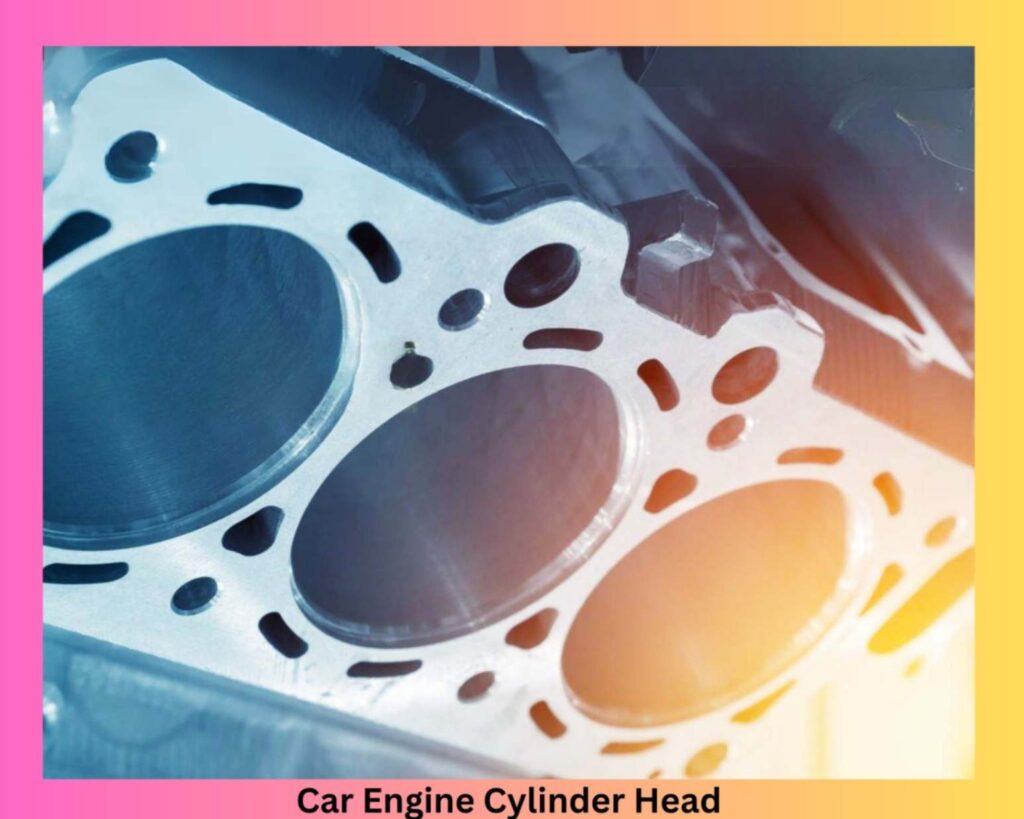

Do cylinder heads need to be resurfaced? If you’re wondering about this critical step in engine repair, you’re not alone. Cylinder heads are vital to engine performance, and resurfacing them can prevent major issues. For car mechanics, owners, and enthusiasts, understanding when and why resurfacing is necessary can save you from costly repairs later.

In this article, we’ll explain what resurfacing does, when it’s needed, and how it impacts engine health. By the end, you’ll clearly understand how this process can help keep your vehicle running smoothly.

Cylinder head resurfacing is a crucial process for maintaining engine performance. It involves removing a thin layer of material from the head to ensure it is flat and able to create a proper seal with the engine block. This prevents issues such as coolant leaks, overheating, and loss of compression.

Resurfacing is typically needed when the cylinder head becomes warped or damaged due to factors like engine overheating, pressure, or regular wear and tear. Without this procedure, the engine’s efficiency and reliability can suffer significantly

Common symptoms indicating the need for resurfacing include:

Overheating is the main factor behind cylinder heads warping or cracking. When the engine overheats, it puts immense stress on the cylinder head, leading to warping. This causes pressure leaks, affecting engine performance.

Do cylinder heads need to be resurfaced when your engine overheats or coolant leaks? Absolutely! Overheating and coolant leaks are often due to cracks or worn-out gaskets. If your engine overheats, steam might pour out of the hood, indicating the need for immediate attention. Resurfacing the cylinder head helps prevent further damage.

Do cylinder heads need to be resurfaced if you notice a loss of power? Yes, they do. A failed head gasket can lead to rough running and power loss. When compression leaks between cylinders, it causes poor engine performance, misfires, and rough idling.

Do cylinder heads need to be resurfaced if oil and coolant mix? Definitely. When oil mixes with coolant, it points to a gasket failure. Resurfacing the cylinder head will fix the uneven surfaces causing the leak.

When preparing to resurface cylinder heads, initial inspection is crucial to ensuring engine performance and preventing further damage. Begin by cleaning the cylinder head thoroughly to remove oil, dirt, and gasket residue. Any leftover contaminants can interfere with the resurfacing process and cause sealing issues. Use a non-abrasive cleaner to avoid damaging the surface. During the inspection, check for signs of warping, cracks, or excessive wear, which can compromise engine performance if not addressed.

For cleaning the surface, avoid abrasive methods such as wire brushes or harsh chemicals that might scratch or warp the head. Opt for a soft cloth and a degreaser, ensuring the head is completely free from contaminants. If cracks or warping are detected, it might require professional assessment.

Resurfacing can be done manually or with a machine. For DIY enthusiasts, flat glass and sandpaper in a cross-hatch pattern can suffice for minor repairs. However, machine methods, like milling or grinding, offer greater precision and are preferred for accuracy, ensuring a smooth surface for optimal gasket sealing.

When resurfacing cylinder heads, achieving the correct surface finish is crucial. The desired roughness (Ra value) depends on the material, such as aluminum or cast iron, and the gasket type. For modern multi-layer steel (MLS) gaskets, smoother finishes are essential to ensure a perfect seal. This attention to detail is key to avoiding engine issues later.

After resurfacing, it’s time for the final inspection to guarantee the job was done right. Checking the cylinder head for flatness using precision tools ensures there’s no warping. A flat surface is necessary for a good seal, especially when installing MLS gaskets.

A critical mistake in resurfacing is removing too much material. This can drastically lower the compression ratio, leading to poor engine performance and reduced power. Over-resurfacing is something every mechanic must avoid to maintain engine integrity. Do Cylinder Heads Need to Be Resurfaced? Yes, but the amount of material removed must be carefully controlled to prevent performance loss.

Using outdated or improper tools can result in uneven surfaces, making proper sealing impossible. If the surface isn’t evenly machined, it can lead to future leaks or other issues. Having the right equipment is key to a successful resurfacing job.

Uneven surfaces cause improper sealing.

Using proper tools ensures smooth, even resurfacing.

Avoid using outdated or damaged equipment.

One of the most common resurfacing errors is not checking flatness both before and after the job. Failing to do so can cause leaks and engine overheating due to improper sealing. Always double-check the flatness to avoid future problems.

Improper flatness leads to leaks.

Double-check flatness to prevent overheating.

Precision checks are essential for a successful resurfacing job.

When resurfacing cylinder heads, proper reassembly is important to maintain engine performance and prevent future issues. Here’s a detailed guide to ensure success during reassembly:

Always replace the head gasket when reassembling the engine after resurfacing. This ensures a proper seal and avoids future leaks, especially if the old gasket has been compromised due to resurfacing or wear.

When tightening the head bolts, use the manufacturer’s specified torque settings and follow the recommended star pattern to evenly distribute pressure. This prevents warping, which can result from uneven tightening.

Before starting the reassembly, double-check the manufacturer’s specifications for torque values. This step ensures that your engine will be properly secured without causing undue stress or damage.

In summary, resurfacing is an essential process for restoring flatness to cylinder heads, but correct reassembly is equally important. If done improperly, it can result in compression loss or seal failures. Following these reassembly tips helps avoid common pitfalls and maintains optimal engine performance

When it comes to the cost of cylinder head resurfacing, you’re looking at an investment between $200 and $500. This may vary depending on the brand, type of engine, and logistic costs at a particular place. While this may feel like a lot upfront, the long-term benefits for your engine’s performance and lifespan are worth it. The exact cost depends on factors like your vehicle’s make, model, and the extent of the damage. Before committing, always get multiple quotes from trusted mechanics to ensure you’re getting the best deal.

Torque specs are essential for cylinder head resurfacing, ensuring a secure fit. Begin by pre-tightening bolts to 50 N/m (37 lb/ft) and follow with a final tightening to 42-45 lb/ft—always without lubrication. Cylinder heads must be tightened in sequence, starting cold. Do cylinder heads need to be resurfaced? Yes, and proper torque specs are critical to avoid leaks and ensure longevity.

In short, resurfacing cylinder heads is important to keep your engine working well. If your car shows signs like overheating, oil leaks, or reduced power, it may be time to resurface the cylinder head. This process smooths out the surface to help your engine run better and avoid more expensive fixes later. By getting the cylinder head resurfaced, you protect your car’s engine and keep it performing smoothly for a longer time

Cylinder head resurfacing involves removing a thin layer of metal to restore its flatness. This helps ensure a proper seal between the head and engine block.

Resurfacing is necessary when the head becomes warped due to overheating, wear, or damage. It helps prevent leaks and improves engine performance.

Common signs include engine overheating, coolant leaks, or loss of compression. These symptoms suggest the head may be warped and need resurfacing

Yes, resurfacing can be done as a DIY project, especially for aluminum heads. However, professional resurfacing is recommended for complex jobs.

Resurfacing typically costs between $200 to $500, depending on the engine type, the number of cylinders , and brand.

It depends on your engine’s condition. Resurfacing is usually done when the head is damaged or warped, not as routine maintenance.

If not resurfaced when needed, the engine may suffer from gasket leaks, reduced performance, or even further damage to the block or cylinder.

Yes, if resurfaced too many times, too much material may be removed, weakening the head and affecting its structural integrity.

Not always. Resurfacing is only needed if the head is warped or damaged. Otherwise, a new gasket alone may be sufficient.

Driving with a warped cylinder head is not recommended. It can lead to engine overheating, leaks, and eventually severe engine damage.