Phone:

(701)814-6992

Physical address:

6296 Donnelly Plaza

Ratkeville, Bahamas.

Valve clearance plays an important role in engine performance, directly impacting compression. When the gap between the valve and the rocker arm is either too large or too small, it can lead to poor combustion, reduced power, and even engine damage. By understanding how valve clearance affects compression, you’ll know why regular adjustments are essential.

For car mechanics and enthusiasts alike, keeping the right valve clearance ensures optimal engine performance. Neglecting this can cause a range of issues. In this article, you will learn how improper valve clearance affects your engine’s compression and what you can do to fix it.

The engine valve is a critical component responsible for regulating the flow of air-fuel mixture into the combustion chamber and expelling exhaust gases. It functions by opening and closing at precise moments, controlled by the camshaft. An engine has two different kinds of valves: intake valves, which let in the air-fuel mixture, and exhaust valves, which release the combustion gases.

Engine valves perform several essential tasks, ensuring smooth engine operation:

Valve clearance, also known as valve lash, is the small gap between the rocker arms and the valve tappet. It ensures proper valve operation. If this gap is too small, the valves won’t seat properly, affecting performance. If it’s too large, it can cause excessive noise and put undue stress on the valve train components.

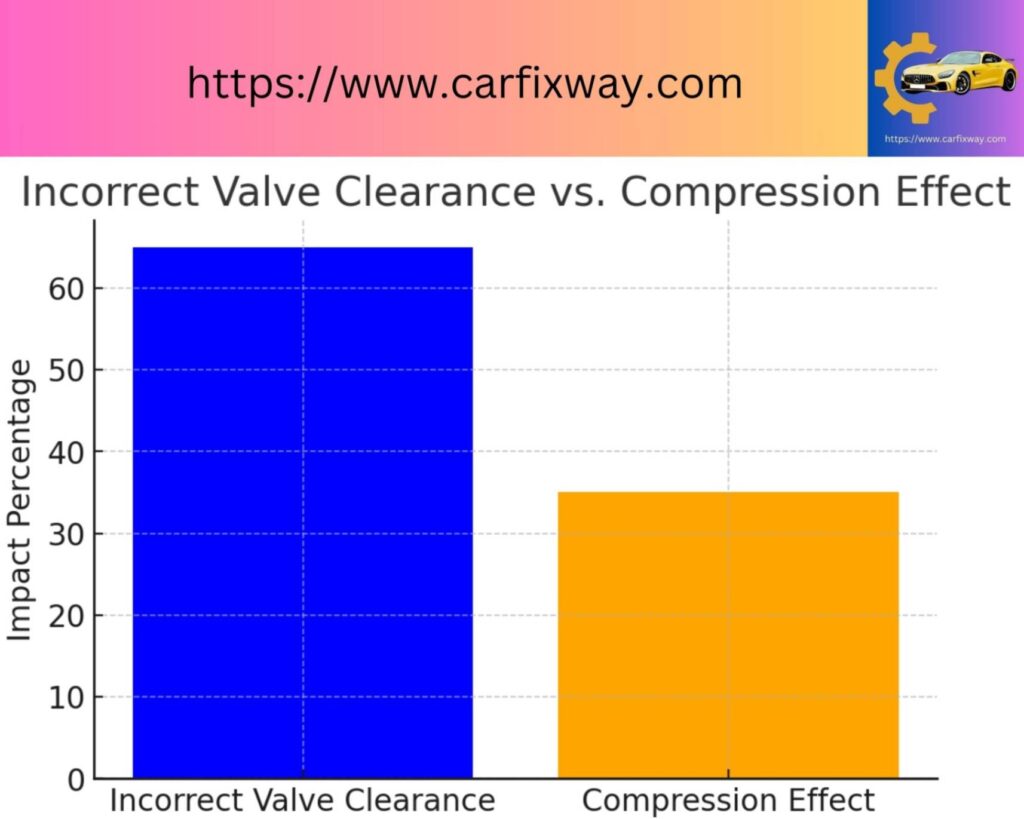

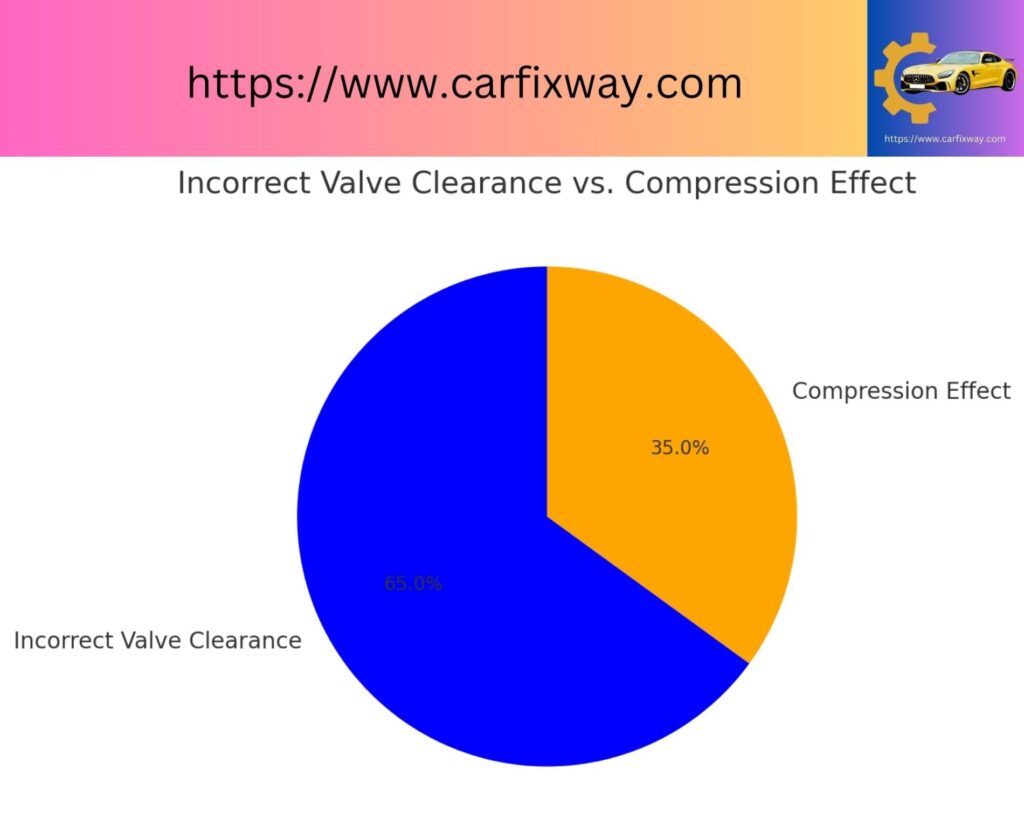

Yes, valve clearance can affect compression. Improper clearance can lead to several issues, including low compression. One common problem is a dropped valve seat, where the metal ring loosens due to heat expansion. This allows air to escape, reducing compression.

Key points:

Excessive valve clearance can severely affect engine performance by causing the valves to open and close improperly. When clearance is too large, valves fail to close fully, leading to poor compression. This incomplete closure allows air to escape from the combustion chamber, reducing power and efficiency. Over time, excessive valve clearance can cause clattering and damage components like valves, camshaft lobes, and rocker arms

When valve clearance is too tight, the valves may overheat because they do not close fully, preventing heat dissipation. This causes valve burnouts, leading to significant loss of compression and power. Insufficient clearance can also result in valve seat recession where continuous leakage erodes the valve seats, worsening the engine’s performance

By maintaining proper valve clearance, you ensure that the engine retains optimal compression and performance.

Incorrect valve clearance can lead to various issues that affect engine performance and longevity. Some common symptoms include:

When valve clearance is either too large or too small, the engine struggles to breathe efficiently. This not only decreases engine performance but can also lead to increased emissions, excessive engine wear, and even catastrophic damage if left unchecked.

Proper valve maintenance ensures smoother engine performance, better fuel economy, and reduced long-term damage.

Valve clearance plays a crucial role in maintaining proper compression in the engine. When intake and exhaust valves become damaged due to extreme heat, they may fail to close properly, leading to compression loss. As gases escape, the cylinder loses pressure, weakening combustion. Variations in valve clearance can disrupt the piston’s ability to create the necessary pressure, affecting the entire combustion process. This can cause low or inconsistent compression.

Incorrect valve clearance often stems from natural wear and tear or poor maintenance. Excessive wear on valve guides or improper reaming during repairs widens valve guide clearance, allowing hot gases to enter, causing carbon buildup on the valve stem. Improper valve seat erosion or lack of proper maintenance can also lead to clearance issues.

To measure and adjust valve clearance, follow these steps for precision:

Accurately following the manufacturer’s specifications for intake and exhaust valves ensures optimal engine performance.

Maintaining proper valve clearance is crucial for engine health and compression. Here are a few tips:

By following these steps, you can keep your engine running smoothly and prevent valve-related issues.

In high-performance racing engines, optimizing valve clearance can significantly impact compression and overall engine performance. Proper valve adjustments ensure that compression is maximized, leading to improved power output. For instance, reducing valve clearance can enhance compression by allowing the valves to close more efficiently, trapping more air and fuel in the combustion chamber.

Key benefits include:

For proper engine performance, valve clearance needs to be within specific ranges. Typically, intake valves should have a clearance of 3-5 thousandths of an inch, and exhaust valves should fall within 5-7 thousandths of an inch. These measurements ensure efficient combustion and prevent issues like valve clatter or leaking.

Basic valve adjustments can be done at home using a feeler gauge and following the manufacturer’s guidelines. However, if you’re dealing with complex engines or tight tolerances, it’s safer to consult a professional to avoid costly mistakes or long-term damage.

Incorrect valve clearance can lead to significant long-term damage, including reduced engine compression, increased wear on the valve train, and overall reduced engine performance. Over time, this can result in costly repairs or even engine failure if left unchecked.

By understanding these key points, you can maintain optimal engine performance while balancing DIY work and professional services.

To wrap up, valve clearance plays a crucial role in maintaining engine compression. If the clearance is too tight, it can result in low compression, causing the engine to struggle with starting and running efficiently. Conversely, if the clearance is too loose, it can disrupt the compression process, negatively affecting engine power and fuel efficiency.

To ensure optimal engine performance and longevity, it’s essential to keep valve clearance within the manufacturer’s specified range. Regular maintenance and timely adjustments will help prevent issues like reduced performance and increased emissions, keeping your engine running smoothly.

Maintaining proper valve clearance is vital not only for the health of the engine but also for maximizing efficiency and performance, whether in daily driving or high-performance conditions.

Yes, improper valve clearance can affect compression. If the clearance is too tight, the valves may not fully close, causing a loss of compression.

Tight valve clearance prevents the valves from closing completely, leading to reduced compression and poor engine performance

Yes, loose valve clearance can lead to slightly higher compression because the valves close earlier than designed, but it can also reduce engine efficiency

Incorrect valve clearance can lead to poor engine performance, causing rough idling, decreased power, or increased fuel consumption

Yes, improper valve clearance, especially when too tight, can cause engine misfires due to incomplete valve closure, leading to poor combustion

Low compression happens because tight valves prevent full closure, allowing air to escape from the combustion chamber

Yes, when the valves are too tight, they can overheat because they aren’t able to dissipate heat properly through the valve seats

Signs include rough idling, strange ticking sounds, reduced power, and engine overheating. A compression test can confirm valve issues

Yes, incorrect valve clearance can lower fuel efficiency as the engine struggles to maintain proper combustion

It’s recommended to check valve clearance during routine maintenance or if you notice performance issues, based on your vehicle’s manual