Phone:

(701)814-6992

Physical address:

6296 Donnelly Plaza

Ratkeville, Bahamas.

The gearbox stands as the unsung hero in your vehicle’s powertrain, orchestrating seamless power delivery from engine to wheels. Whether you’re navigating city traffic or cruising on highways, this mechanical marvel ensures your vehicle responds precisely to every driving demand. Understanding its components and functions empowers you to maintain peak performance and catch problems before they escalate into costly repairs.

A gearbox serves as the vital bridge between your engine’s raw power and the wheels that move your vehicle. This sophisticated mechanical system transforms high-speed, low-torque engine output into the precise combination of speed and torque your driving situation demands. Think of it as a translator that speaks both engine language and wheel language fluently.

Modern vehicles rely on gearboxes to optimize performance across diverse conditions:

The gearbox functions as a speed reducer and torque multiplier in your vehicle’s drivetrain. Without this component, your engine would struggle to provide sufficient force at low speeds while simultaneously limiting your top speed potential. Engineers design gearboxes with multiple gear ratios that allow engines to operate within their most efficient RPM range regardless of vehicle speed.

Your engine produces maximum power at high RPMs, but wheels need high torque at low speeds:

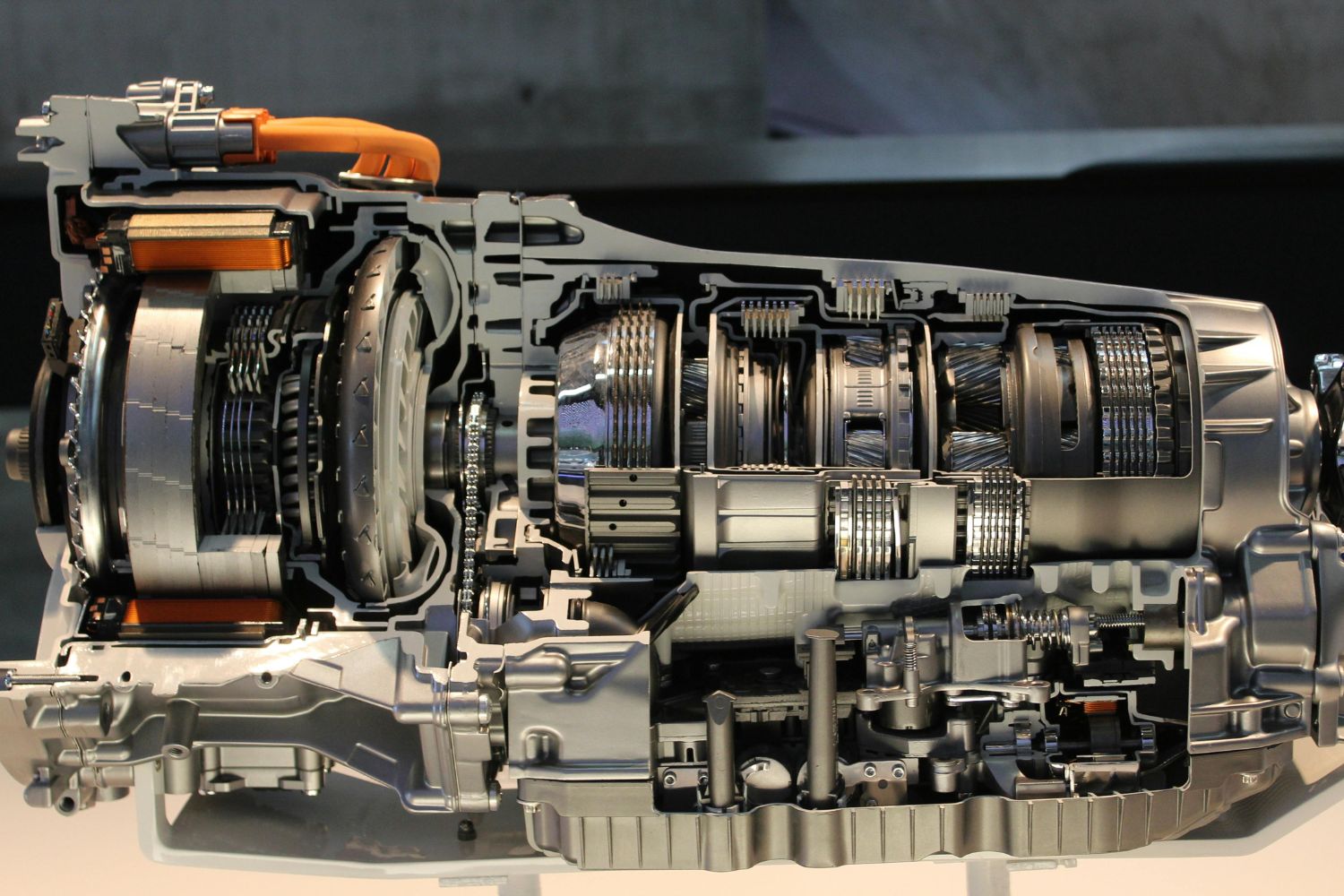

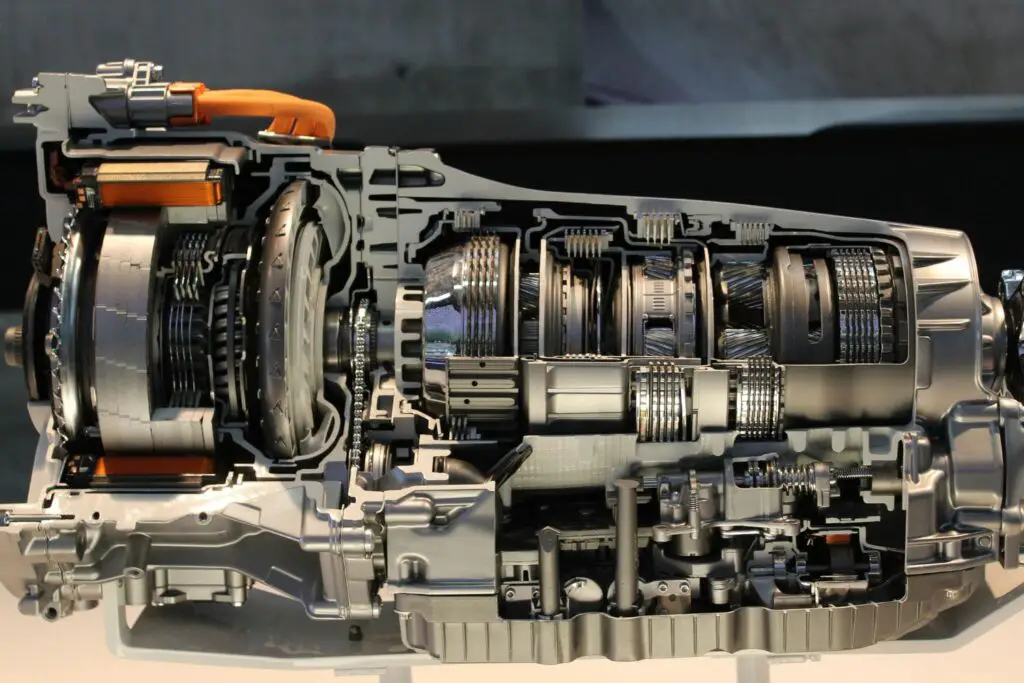

The mechanical connection flows through a series of rotating components that transmit power while modifying its characteristics. The input shaft receives power directly from the engine’s crankshaft, passing through either a clutch assembly in manual transmissions or a torque converter in automatics. This power then travels through selected gear combinations before exiting via the output shaft to the driveshaft or axles.

The connection involves precise mechanical synchronization:

Gear ratios determine how many times the input shaft rotates for each output shaft revolution. A 3:1 ratio means the engine spins three times while the output shaft completes one rotation, tripling the torque but reducing speed proportionally. Lower numerical ratios (like 0.7:1 overdrive) do the opposite, sacrificing torque for increased speed and improved fuel economy on highways.

Understanding gear ratios helps you appreciate your vehicle’s capabilities:

Manual transmissions require driver intervention to select gears using a clutch pedal and shift lever, offering direct control over power delivery. Automatic transmissions handle gear selection independently using hydraulic systems, electronic sensors, and sophisticated computer algorithms that analyze driving conditions continuously. Each type presents distinct advantages regarding control, efficiency, maintenance requirements, and driving experience.

The fundamental differences affect daily driving significantly:

The gearbox operates on fundamental mechanical principles that have remained consistent for over a century. When you select a gear, you’re essentially choosing which set of interlocking toothed wheels will transmit power from engine to wheels. These gears mesh together with precise tolerances, with smaller gears driving larger ones for torque multiplication or larger gears driving smaller ones for speed increase.

The magic happens through carefully engineered gear interactions:

Torque and speed exist in an inverse relationship within gearbox operation—increasing one necessarily decreases the other. When first gear engages, a small input gear drives a large output gear, rotating the output shaft slower than the input while multiplying available torque significantly. As you shift to higher gears, the size relationship reverses, allowing higher speeds with reduced torque output.

This principle enables vehicles to perform diverse tasks:

Gears mount on shafts using splines, keyways, or bearings that allow either fixed or free rotation depending on design requirements. In constant-mesh transmissions, all gears remain engaged continuously while dog clutches or synchronizers lock selected gears to their shafts. The input shaft, intermediate shaft (also called layshaft or countershaft), and output shaft work in concert to provide multiple gear ratio options through strategic gear placement and sizing.

The shaft arrangement creates a compact yet versatile system:

The clutch serves as a controllable coupling between engine and transmission, allowing drivers to interrupt power flow during gear changes. Pressing the clutch pedal disengages two friction plates—one connected to the engine’s flywheel and another to the transmission input shaft. This disconnection lets you select new gears without grinding teeth, while gradual clutch release smoothly reestablishes power flow at the chosen gear ratio.

Proper clutch operation ensures transmission longevity:

Planetary gear sets revolutionized automatic transmissions with their compact design and multiple ratio possibilities. Each set contains a central sun gear, multiple planet gears mounted on a carrier, and an outer ring gear surrounding everything. By selectively holding or releasing these components using clutches and bands, automatic transmissions achieve different gear ratios without disengaging power flow, resulting in smooth, uninterrupted acceleration.

This elegant system offers significant advantages:

Modern automotive engineering offers diverse transmission technologies, each optimized for specific performance characteristics, driver preferences, and vehicle applications. From traditional manuals that provide ultimate driver control to sophisticated automatics that optimize every shift, understanding these variations helps you appreciate your vehicle’s capabilities and maintenance requirements.

Transmission technology continues evolving rapidly:

Manual transmissions feature driver-operated gear selection using a clutch pedal and shift lever connected to the transmission via linkages or cables. Inside the housing, you’ll find constant-mesh helical gears on the input and layshaft, with synchronizer assemblies on the output shaft that lock selected gears in place. The shift forks, operated by the shift lever, move synchronizers along the output shaft to engage different gears, while the clutch temporarily disconnects engine power during transitions.

Key components work together seamlessly:

Automatic transmissions replace the mechanical clutch with a fluid-filled torque converter that provides smooth power transfer while allowing the engine to idle independently. Planetary gear sets combine with hydraulic clutch packs and brake bands, controlled by a sophisticated valve body that directs pressurized transmission fluid. Modern automatics incorporate electronic control units (ECUs) that monitor vehicle speed, throttle position, and engine load to determine optimal shift points and transmission behavior.

The complex system requires multiple components:

CVTs eliminate fixed gear ratios entirely, using a belt or chain running between two variable-diameter pulleys. As pulley diameters adjust continuously, the transmission provides an infinite number of gear ratios within its operating range. This seamless ratio adjustment keeps engines operating at their most efficient RPM regardless of vehicle speed, maximizing fuel economy though sometimes at the expense of the engaging driving feel traditional transmissions provide.

CVT technology offers unique benefits:

Dual-clutch transmissions (DCTs) combine manual transmission efficiency with automatic convenience using two separate clutches—one for odd-numbered gears and another for even-numbered gears. While one clutch transmits power in the current gear, the other pre-selects the next anticipated gear, enabling lightning-fast shifts without power interruption. Semi-automatic transmissions use similar principles but may employ single-clutch designs with automated clutch operation and gear selection based on driver input or computer control.

These advanced systems deliver impressive performance:

Recognizing early warning signs of gearbox problems can save you thousands in repair costs and prevent dangerous breakdowns. Your transmission communicates its health through sounds, sensations, and behaviors that deviate from normal operation. Paying attention to these signals and addressing them promptly ensures reliable transportation and prevents secondary damage to other drivetrain components.

Early detection prevents catastrophic failures:

Grinding, whining, or clunking noises from your transmission indicate internal components experiencing abnormal wear or insufficient lubrication. Grinding during gear changes typically points to worn synchronizers in manual transmissions or damaged clutch packs in automatics. Whining sounds often result from worn bearings, while clunking may indicate loose or broken internal components bouncing around inside the transmission housing.

Hard shifts, missed gears, or gears popping out of engagement indicate serious transmission concerns requiring immediate diagnosis. In manual transmissions, shifting difficulty usually stems from worn synchronizers, damaged shift forks, or clutch problems preventing complete disengagement. Automatic transmissions experiencing shift problems may have valve body issues, worn clutch packs, or electronic control failures affecting hydraulic pressure and gear engagement.

Shifting problems progressively worsen without intervention:

Red or brown fluid pooling beneath your vehicle indicates transmission seal or gasket failure, potentially leading to catastrophic damage if fluid levels drop too low. Transmission fluid serves multiple critical functions—lubricating moving parts, cooling the transmission, and in automatics, providing hydraulic pressure for gear changes. Operating with insufficient fluid causes rapid wear, overheating, and eventual complete transmission failure requiring expensive replacement.

Fluid leaks demand immediate attention:

Automatic transmissions should shift smoothly and predictably at consistent speed intervals, so delayed engagement when shifting into drive or reverse signals problems with hydraulic pressure, valve body operation, or clutch pack condition. Erratic shifting—unexpected gear changes at wrong speeds or harsh shifts—often results from electronic control issues, worn transmission bands, or contaminated fluid affecting hydraulic system operation.

Shift quality directly reflects transmission health:

Understanding individual gearbox components helps you appreciate the engineering complexity hidden inside that seemingly simple housing bolted to your engine. Each component performs specific functions that contribute to overall transmission operation, and failure of any single part can compromise entire system performance. Modern transmissions contain hundreds of precision-manufactured components working in harmony to deliver reliable power transmission.

Component quality determines transmission longevity:

Gears represent the fundamental working elements of any transmission, converting rotational speed and torque through their size relationships and tooth engagement. Different gear types suit specific applications based on their efficiency, noise characteristics, load capacity, and spatial requirements. Modern transmissions strategically combine various gear types to optimize performance, durability, and packaging constraints within available space.

Gear selection affects transmission characteristics:

Spur gears feature straight teeth parallel to the gear axis, offering simple manufacturing and high efficiency for power transmission. Their straightforward design makes them cost-effective and easy to produce, though they generate more noise than helical alternatives due to sudden tooth engagement along the entire tooth width simultaneously. You’ll find spur gears in some manual transmission reverse gear configurations and older transmission designs where their simplicity outweighed their noise disadvantages.

These basic gears serve specific purposes:

Helical gears incorporate teeth cut at an angle to the gear axis, creating gradual engagement that significantly reduces noise and vibration compared to spur gears. The angled teeth distribute load across multiple teeth simultaneously, increasing load capacity and extending gear life despite introducing axial thrust forces requiring thrust bearings. Modern transmissions predominantly use helical gears for all forward speeds due to their superior refinement and durability.

The angled tooth design provides advantages:

Bevel gears feature conical shapes that allow power transmission between intersecting shafts, typically at 90-degree angles. You’ll find these gears in differential assemblies where they redirect power from the driveshaft to the axle shafts driving the wheels. Spiral bevel gears, with curved teeth similar to helical gears, offer quieter operation and higher strength than straight-cut bevel gears, making them standard in modern differentials.

These specialized gears handle unique requirements:

Planetary gear sets pack incredible versatility into compact spaces, featuring a central sun gear, multiple planet gears rotating on a carrier, and an outer ring gear. By holding different components stationary or connecting them together using clutches and bands, a single planetary set produces multiple gear ratios. Modern automatic transmissions stack multiple planetary sets to achieve six, eight, or even ten forward speeds while maintaining smooth power delivery during shifts.

This ingenious design revolutionized automatic transmissions:

Shafts form the backbone of transmission operation, supporting gears and transmitting rotational force through the gearbox. These precisely machined steel components must withstand enormous torsional stresses while maintaining perfect alignment and minimal friction. Bearing surfaces, splines, and mounting points require exacting tolerances to ensure smooth operation and prevent premature wear.

Shaft integrity determines transmission reliability:

The input shaft connects directly to the engine crankshaft through the clutch assembly in manual transmissions or torque converter in automatics, receiving full engine power and rotating at engine speed. This shaft typically supports the primary drive gear that meshes with the layshaft, initiating power flow through the transmission. Input shafts endure significant stress from engine torque fluctuations and must be manufactured from high-strength alloy steel with proper heat treatment.

This critical component initiates power transfer:

The output shaft delivers power from the selected gear combination to the driveshaft or differential, rotating at speeds determined by the engaged gear ratio. In manual transmissions, gears either mount directly on the output shaft via splines or rotate freely on bearings until locked by synchronizers. The output shaft’s rotation speed relative to input shaft speed defines the current gear ratio and determines vehicle speed for a given engine RPM.

This shaft completes the power delivery chain:

The intermediate shaft (also called countershaft or layshaft) bridges input and output shafts, supporting clusters of gears that mesh with corresponding gears on other shafts. This shaft typically has gears permanently attached that rotate as a unit, providing multiple ratio options through strategic gear sizing. Three-shaft transmissions using this design allow more gear ratios in compact packages compared to two-shaft configurations.

This auxiliary shaft enables multiple ratios:

Shafts and gears connect through various methods depending on whether fixed or selective engagement is required. Splines—longitudinal grooves and ridges—provide positive engagement allowing rotational force transfer while permitting limited axial movement for synchronizer operation. Bearings support gears that must rotate freely until engaged, while press fits or lock rings secure gears requiring permanent attachment to their shafts.

Multiple connection methods serve different purposes:

Synchronizers represent one of the most ingenious solutions in transmission engineering, enabling smooth gear changes without grinding by matching rotational speeds before engagement. These assemblies make modern manual transmissions pleasant to operate compared to older crash-box designs requiring double-clutching. Understanding synchronizer function helps you appreciate why gentle shifting extends transmission life.

Synchronizer condition directly affects shift quality:

Synchronizers function as speed-matching devices that bring a freewheeling gear up to shaft speed before locking it in place. When you move the shift lever, the synchronizer hub—splined to the output shaft—slides a sleeve toward the target gear. Friction rings contact the gear’s cone surface, using friction to accelerate or decelerate the gear until it matches shaft speed, at which point dog teeth engage and lock the gear solidly to the shaft.

The synchronization process happens in milliseconds:

The conical friction surfaces generate just enough resistance to overcome the gear’s rotational inertia, bringing it to the correct speed through controlled slipping. The synchronizer’s blocking ring prevents dog teeth engagement until speeds match sufficiently, protecting transmission internals from damage. This mechanical interlock ensures proper synchronization before allowing full engagement, though forcing shifts can overcome the blocking mechanism and cause grinding.

Speed matching prevents mechanical damage:

A complete synchronizer assembly includes a hub splined to the shaft, a sliding sleeve with internal teeth, friction blocking rings with conical surfaces, and small springs or detent balls providing neutral position retention. The friction material on blocking rings wears gradually during normal operation, eventually losing effectiveness and causing grinding shifts. High-performance transmissions may use carbon-fiber or brass alloy synchronizers for enhanced durability under demanding conditions.

Multiple parts work together seamlessly:

Grinding noises during gear engagement clearly indicate worn synchronizer friction surfaces no longer effectively matching speeds before dog teeth attempt engagement. Difficulty entering certain gears or gears popping out of engagement also suggest synchronizer problems, as worn components fail to maintain positive lockup. Second gear typically wears fastest due to frequent use during acceleration, making it the first to show problems.

Progressive wear produces recognizable symptoms:

These components manage the critical connection between engine and transmission, allowing power interruption for gear changes while providing smooth engagement from standstill. The clutch in manual transmissions and torque converter in automatics perform similar functions through entirely different mechanisms—one purely mechanical, the other using fluid dynamics. Both require periodic maintenance and eventual replacement as wear inevitably occurs.

Connection devices enable transmission operation:

The clutch assembly contains a pressure plate, clutch disc, and release bearing working together to engage and disengage power flow. When you press the clutch pedal, hydraulic or cable pressure forces the release bearing against the pressure plate’s diaphragm spring, releasing clamping force on the clutch disc. This allows the disc—sandwiched between the flywheel and pressure plate—to separate slightly, interrupting power transmission while engine and transmission rotate independently.

The mechanical disengagement follows predictable steps:

The role of the torque converter in automatics

Torque converters use fluid coupling to transfer engine power to transmission input shaft without direct mechanical connection. Three main elements—pump (connected to engine), turbine (connected to transmission), and stator (redirecting fluid flow)—circulate transmission fluid in a toroidal pattern. At low speeds, the stator multiplies torque up to 2:1, while at highway speeds the converter lockup clutch engages for direct mechanical connection and improved efficiency.

Fluid dynamics enable smooth power transfer:

Hydraulic systems vs. mechanical systems

Hydraulic clutch actuation uses fluid pressure to transmit pedal force to the release bearing, offering smoother operation and reduced pedal effort compared to cable systems. Automatic transmissions rely entirely on hydraulic pressure—typically 50-250 psi—to engage clutch packs and brake bands selecting different gears. Mechanical linkages in manual transmissions provide direct connection but require more pedal effort and periodic adjustment.

Each system offers distinct characteristics:

Maintenance tips for clutches and torque converters

Clutches wear gradually through normal operation, with lifespan heavily influenced by driving habits—frequent starts on hills or excessive slipping accelerates wear dramatically. Avoid riding the clutch pedal and ensure complete disengagement during shifts to maximize clutch life. Torque converters require clean transmission fluid at proper levels for cooling and hydraulic function; contaminated fluid damages internal components and causes shuddering during engagement.

Proper maintenance extends component life:

Modern gearboxes incorporate sophisticated engineering that dramatically enhances vehicle capability, efficiency, and driver satisfaction. These mechanical marvels represent over a century of refinement, with contemporary designs leveraging advanced materials, electronic control, and precision manufacturing to deliver unprecedented performance and reliability. Understanding these features helps you appreciate the technology under your vehicle.

Advanced engineering delivers tangible benefits:

Today’s transmissions pack impressive capabilities into relatively compact housings, employing technologies that would amaze engineers from just decades ago. From advanced gear tooth profiles optimized through computer simulation to multi-speed automatic transmissions rivaling manual efficiency, modern gearboxes represent pinnacles of mechanical engineering. These features combine to deliver the smooth, efficient, and reliable operation that drivers expect.

Contemporary transmissions incorporate cutting-edge technology:

Multiple gear ratios allow engines to operate within optimal RPM ranges across diverse driving conditions, from aggressive acceleration requiring maximum torque to efficient highway cruising prioritizing fuel economy. Modern transmissions offer six to ten forward speeds in automatics and typically five or six in manuals, providing finer ratio spacing that keeps engines in their power band. Wide ratio spreads between lowest and highest gears enable both strong low-speed pulling power and efficient high-speed operation.

Ratio selection determines vehicle capability:

Transmission housings use cast aluminum or magnesium alloys providing strength while minimizing weight, with internal components manufactured from heat-treated alloy steels capable of withstanding tremendous stresses. Precision machining achieves tolerances measured in thousandths of inches, ensuring proper component interaction and minimal wear. Modern manufacturing quality enables many transmissions to exceed 200,000 miles with proper maintenance, far surpassing historical expectations.

Quality construction ensures reliability:

Contemporary transmissions adapt to diverse powerplants, from fuel-efficient four-cylinder engines to powerful V8s and even hybrid electric systems combining internal combustion with electric motors. Manufacturers design transmission families scalable across multiple engine outputs through variations in gear sizing, clutch capacity, and cooling provisions. This flexibility allows automakers to use common transmission architectures across vehicle lineups, reducing development costs while maintaining performance.

Design flexibility enables wide application:

Electronic control revolutionized automatic transmissions, replacing mechanical governors with computers analyzing dozens of inputs—vehicle speed, engine load, throttle position, brake application, and even road grade—to optimize shift patterns continuously. These systems adapt to driving style, providing aggressive shifts during spirited driving or gentle transitions during relaxed cruising. Some transmissions even use GPS data to anticipate upcoming road conditions and pre-select appropriate gears.

Electronics enable intelligent transmission operation:

Regular maintenance preserves transmission performance and prevents expensive failures that often total more than vehicle value. Simple practices like fluid changes remove accumulated contaminants before they damage delicate components, while periodic inspections catch developing problems early when repairs remain affordable. A well-maintained transmission delivers years of reliable service with minimal unexpected expenses.

Preventive maintenance delivers significant returns:

A healthy transmission responds precisely to throttle inputs, delivering power smoothly and predictably across the entire speed range. Properly functioning transmissions shift at optimal points for acceleration, maintaining engine RPM in the power band for maximum performance. Worn or malfunctioning transmissions hesitate, slip, or shift erratically, robbing power and making vehicles feel sluggish despite mechanically sound engines.

Transmission condition affects driving experience profoundly:

Efficient transmissions minimize power losses through friction and deliver power to wheels with minimal waste, directly impacting fuel consumption. Automatics with numerous gears keep engines operating at optimal efficiency points more consistently than transmissions with fewer ratios. Torque converter lockup eliminates fluid coupling losses at cruising speeds, while CVTs maintain ideal engine speeds regardless of vehicle velocity.

Efficiency directly affects operating costs:

Well-maintained transmissions shift seamlessly without jerking or harshness, creating a refined driving experience that makes journeys more pleasant. Fresh transmission fluid maintains proper hydraulic pressure and lubrication, preventing the groaning or whining sounds that indicate excessive wear or insufficient lubrication. Quality synchronizers in manual transmissions enable effortless gear changes without grinding that both irritates drivers and indicates component damage.

Refinement matters for long-distance comfort:

Properly functioning transmissions protect other drivetrain components from damaging shock loads and excessive stress. Smooth power delivery prevents driveshaft vibration, differential wear, and axle stress that result from harsh shifting or gear slippage. By maintaining appropriate gear selection, transmissions prevent engine lugging at low RPMs or over-revving that damages internal engine components and reduces their service life.

Component protection reduces total ownership costs:

Understanding transmission operation benefits both drivers and technicians, maintaining vehicles. Drivers armed with knowledge can operate vehicles more efficiently and recognize problems early, while mechanics appreciate customers who understand basic transmission principles and maintenance importance. This mutual understanding facilitates better communication and more effective vehicle care.

Knowledge empowers better decision-making:

Modern transmissions handle diverse conditions—from stop-and-go city traffic to high-speed interstate cruising, mountainous terrain to trailer towing—delivering consistent performance throughout. Advanced cooling systems prevent overheating during demanding use, while robust construction withstands the stresses of varied driving styles. This versatility means you can confidently use your vehicle across its full capability range without transmission concerns.

Adaptability enhances vehicle utility:

Regular transmission service costs a fraction of repair or replacement expenses, making scheduled maintenance an exceptional investment. Simple fluid changes typically cost $150-300 but prevent thousands in repair bills from contaminated fluid damage. Catching problems early—through fluid analysis or diagnostic scans—allows targeted repairs before minor issues cascade into major failures requiring transmission replacement.

Prevention dramatically beats repair costs:

Easier troubleshooting with modern diagnostics

Electronic transmissions continuously monitor their operation, detecting problems and storing diagnostic codes that pinpoint specific failures. Scan tools access these codes, dramatically simplifying troubleshooting compared to older transmissions requiring extensive disassembly for diagnosis. Transmission control modules track shift patterns, slippage, and component temperatures, identifying developing problems before they cause breakdowns.

Technology simplifies problem identification:

Predictable transmission behavior enhances vehicle control during emergency maneuvers, with smooth power delivery preventing traction loss or unexpected vehicle behavior. Reliable downshifts provide engine braking on descents, reducing brake wear and fade risk. Transmissions that maintain proper gear selection prevent dangerous situations like insufficient power for passing maneuvers or unintended acceleration from stuck components.

Reliable operation contributes to active safety:

Proactive transmission maintenance prevents expensive failures while maximizing service life and maintaining like-new performance. Unlike engines that provide clear warning signs before failure, transmissions often fail suddenly after prolonged neglect, leaving drivers stranded with repair bills exceeding vehicle value. Understanding maintenance requirements and recognizing early warning signs protects your investment and ensures reliable transportation.

Strategic maintenance prevents catastrophic failures:

Establishing a regular maintenance schedule appropriate for your vehicle and driving conditions preserves transmission health throughout vehicle life. Manufacturers provide baseline service intervals, but severe-duty operation—frequent towing, extreme temperatures, or mountainous terrain—requires more frequent attention. Simple maintenance tasks performed regularly prevent the component failures that necessitate expensive repairs or complete transmission replacement.

Consistent care delivers long-term benefits:

Transmission fluid serves multiple critical functions—lubricating moving parts, cooling components, transferring hydraulic pressure, and preventing corrosion—making regular changes essential for transmission longevity. Most manufacturers recommend fluid changes every 30,000-60,000 miles for normal driving, with more frequent changes for severe service. Check fluid level and condition monthly using the dipstick, looking for proper level, clean red color, and absence of burning odor that indicates overheating damage.

Fluid condition directly reflects transmission health:

Transmission seals and gaskets deteriorate over time from heat cycling, chemical exposure, and normal aging, eventually allowing fluid to escape. Check regularly beneath your vehicle for red or brown fluid indicating transmission leaks, and inspect seal areas around the pan, input/output shafts, and cooler lines for wetness or seepage. Address leaks promptly before low fluid levels cause internal damage requiring expensive repairs far exceeding seal replacement costs.

Early leak detection prevents major damage:

Your transmission communicates its condition through sounds that change as components wear or fail. Whining noises often indicate bearing wear or insufficient fluid, while grinding suggests synchronizer problems in manuals or clutch pack damage in automatics. Clunking during shifts or acceleration reveals loose components or worn mounts, and buzzing at specific speeds may indicate torque converter issues requiring attention.

Sound changes reveal developing problems:

Professional technicians possess diagnostic equipment and experience to detect problems invisible to vehicle owners, identifying issues before they cause breakdowns. Annual transmission inspections should include fluid analysis, checking contamination levels, electronic system scans revealing stored trouble codes, and physical examination of seals, mounts, and cooler lines. These preventive checks typically cost $50-150 but can save thousands by catching problems early.

Expert evaluation provides valuable insights:

Transmission problems range from simple fixes like topping off low fluid to complete rebuilds or replacements costing thousands. Understanding common issues helps you recognize symptoms early when repairs remain manageable and affordable. Many transmission problems develop gradually, providing warning signs that allow intervention before catastrophic failure occurs.

Problem recognition enables timely repairs:

Transmission fluid leaks appear as red or brown puddles beneath your vehicle, typically concentrated near the transmission location between engine and wheels. Common leak sources include the transmission pan gasket, input/output shaft seals, cooler line connections, and torque converter seal. Differentiate transmission fluid from other vehicle fluids by its distinctive red color (when fresh) or brown appearance (when aged), and slightly sweet petroleum odor.

Leak identification requires systematic inspection:

Difficult gear engagement in manual transmissions typically results from worn synchronizers, inadequate clutch disengagement, or linkage problems preventing full shifter travel. Automatic transmissions experiencing hard or missed shifts may suffer from low fluid levels, contaminated fluid affecting hydraulic pressure, worn clutch packs, or electronic control issues preventing proper solenoid operation. Diagnostic scans reveal electronic problems, while fluid inspection indicates contamination or level issues.

Multiple factors cause shifting problems:

Automatic transmissions generate significant heat during operation, particularly when towing, climbing grades, or operating in hot climates. Overheating breaks down transmission fluid rapidly, destroying its lubricating and hydraulic properties while creating varnish deposits on internal components. Install an auxiliary transmission cooler for vehicles used in demanding conditions, ensure proper cooling system operation, and avoid excessive slipping by selecting appropriate gears manually when towing or climbing.

Heat management prevents fluid breakdown:

Synchronizer replacement requires transmission removal and disassembly, but remains far more affordable than complete transmission replacement. Worn synchronizers causing grinding shifts should be replaced promptly before metal particles contaminate fluid and damage other components. Gear replacement becomes necessary when teeth show significant wear, pitting, or breakage, though proper maintenance and gentle shifting typically allow gears to last the vehicle’s lifetime.

Component replacement restores proper operation:

Performance enthusiasts and vehicles used in demanding applications benefit from upgraded transmission components offering enhanced durability, improved shift quality, or increased torque capacity. While stock transmissions suit most drivers perfectly, certain upgrades address specific needs like racing, heavy towing, or off-road use. Upgraded components often cost more initially but provide superior performance and longevity under extreme conditions.

Strategic upgrades enhance capability:

Aftermarket gear sets manufactured from superior materials with improved heat treatment withstand substantially higher torque than stock components, essential for modified engines producing increased power. Performance gears often feature optimized tooth profiles reducing friction and noise while improving strength. These upgrades suit vehicles with engine modifications, forced induction, or racing applications where stock components would fail under extreme loads.

Enhanced gears suit demanding use:

Heavy-duty transmission housings offer increased rigidity and improved bearing support, preventing case flexing that causes bearing failure and gear misalignment under extreme loads. Some reinforced housings incorporate additional cooling fins improving heat dissipation, while others add structural webbing at high-stress areas. These upgrades benefit vehicles regularly towing near capacity or subjected to severe off-road abuse.

Structural improvements enhance durability:

Performance synchronizers using carbon-fiber or brass alloy friction materials offer superior durability and more positive engagement than stock components. These upgraded parts enable quicker shifts without grinding, benefiting both performance driving and normal operation. Some synchronizers feature multiple friction cones increasing torque capacity and shift quality, particularly valuable in transmissions handling increased engine power.

Premium synchronizers improve shift quality:

Synthetic transmission fluids maintain viscosity across wider temperature ranges than conventional fluids, providing superior protection during cold starts and extreme heat conditions. These advanced lubricants contain friction modifiers and anti-wear additives that protect components more effectively than standard fluids. While costing more initially, synthetic fluids often allow extended drain intervals and provide measurably better protection, particularly in performance or heavy-duty applications.

Advanced fluids offer superior protection:

Transmission replacement represents a major expense requiring careful analysis of repair costs versus replacement benefits. Modern transmissions often cost $3,000-8,000 installed, potentially exceeding vehicle value for older cars. However, replacement may prove more economical than repeatedly repairing a transmission with multiple failing components, and upgraded transmissions can transform vehicle performance and capability.

Replacement decisions require careful evaluation:

Catastrophic internal failures—shattered gears, cracked housings, or severely damaged planetaries—typically render transmissions beyond economical repair. Metal contamination throughout the transmission from component failure often damages every internal part, making complete replacement more sensible than attempting rebuilds requiring extensive parts replacement. Transmission cases cracked from impacts or severe overheating cannot be reliably repaired and necessitate complete replacement.

Some damage exceeds repair feasibility:

Compare total repair costs including labor, parts, and potential warranty against replacement transmission prices from various sources—new, remanufactured, or used units. Factor in remaining vehicle value, expected future service life, and repair reliability when making decisions. Sometimes spending $2,000 repairing a transmission in a vehicle worth $8,000 makes sense, while the same repair proves foolish for a vehicle worth $3,000.

Financial analysis guides wise decisions:

Replacing failed transmissions presents opportunities to upgrade to superior designs offering better performance, efficiency, or reliability. Some enthusiasts swap manual transmissions for automatics (or vice versa), while others install transmissions with additional gears or higher torque capacity. These upgrades often require additional components like controllers, wiring, or crossmembers but can dramatically improve vehicle capability.

Upgrades transform vehicle character:

Source replacement transmissions from reputable suppliers offering warranties and quality guarantees, avoiding questionable used units of unknown history. Remanufactured transmissions from established rebuilders often provide the best value, combining like-new condition with warranties and significantly lower costs than new units. Verify compatibility with your specific vehicle—year, engine, and drivetrain configuration—before purchasing, as seemingly identical transmissions often differ in critical details.

Quality sourcing ensures reliability:

Final Thought

Your vehicle’s gearbox represents sophisticated engineering that transforms raw engine power into precise, controllable motion across diverse driving conditions. Understanding its components—from intricate gear sets and synchronizers to input shafts and clutch assemblies—empowers you to maintain this critical system properly and recognize problems before they escalate into expensive failures. Regular maintenance costs mere hundreds of dollars but prevents thousands in repair expenses while ensuring the reliable performance you depend on daily.

Whether you drive a manual transmission requiring periodic clutch replacement and synchronizer attention, or an automatic demanding regular fluid changes and electronic diagnostics, basic knowledge guides better maintenance decisions and more effective communication with service professionals. Modern transmissions incorporate advanced materials, precision manufacturing, and electronic control delivering unprecedented efficiency and longevity when properly cared for. Invest in your transmission’s health through scheduled maintenance, prompt problem resolution, and quality fluids—your vehicle will reward you with years of smooth, reliable service that makes every journey more enjoyable and confident.

Check your transmission fluid monthly as part of routine vehicle inspection, examining both level and condition using the dipstick when the engine is warm and running on level ground. Most manufacturers recommend complete fluid changes every 30,000-60,000 miles for normal driving conditions, though severe service—frequent towing, extreme temperatures, or stop-and-go city driving—requires more frequent changes at 15,000-30,000 mile intervals. Dark brown fluid, burnt odor, or visible metal particles indicate immediate fluid change needs regardless of mileage.

Driving with worn synchronizers risks additional transmission damage as grinding during shifts creates metal particles that contaminate fluid and accelerate wear on other components. While you can temporarily operate the vehicle using careful double-clutching techniques to match gear speeds manually, continued operation without repair allows metal contamination throughout the transmission. Address synchronizer problems promptly to prevent expensive secondary damage requiring complete transmission rebuild rather than simple synchronizer replacement.

Synchronizer failure consequences:

Complete transmission replacement costs vary dramatically based on vehicle type, transmission design, and component source, ranging from $1,500 for used units in economy cars to $8,000 or more for new transmissions in luxury or performance vehicles. Remanufactured transmissions typically cost $2,500-5,000 installed, offering good balance between reliability and affordability. Labor alone often exceeds $1,000 due to complexity and time required for removal, installation, and fluid filling.

Typical replacement cost ranges:

Manual transmissions require driver input for all gear selection using a clutch pedal to disengage power and a shift lever to select gears mechanically, offering direct control and typically better fuel efficiency. Automatic transmissions handle all gear selection independently using hydraulic systems, electronic sensors, and computer control that analyzes driving conditions to optimize shifts without driver intervention. Manuals generally cost less to purchase and maintain but demand more driver attention, while automatics provide convenience and consistent performance regardless of driver skill.

Key operational differences:

Transmission slipping—temporary loss of power during acceleration or between shifts—typically results from worn clutch packs in automatic transmissions or damaged clutch disc in manual transmissions, both allowing rotational speed differences between input and output without full power transfer. Low fluid levels, contaminated fluid reducing hydraulic pressure, or internal seal failures also cause slipping. Address slipping immediately as continued operation generates excessive heat that rapidly damages remaining components and transforms manageable repairs into complete transmission failure.

Common slipping causes:

CVT transmissions demand specific fluids formulated for their unique steel belt or chain designs, and using incorrect fluid causes rapid wear and expensive failures. Most manufacturers recommend CVT fluid changes every 30,000-60,000 miles, similar to conventional automatics, though some claim lifetime fills that experienced technicians recommend changing anyway around 60,000 miles. CVTs operate under higher internal pressures than conventional automatics, making fluid condition even more critical for longevity and proper operation.

Require manufacturer-specified CVT fluids only

Regular fluid changes despite lifetime claims

Proper maintenance prevents expensive failures

CVT-specific maintenance needs:

What causes transmission overheating?

Transmission overheating results from excessive load during towing or climbing grades, insufficient cooling from blocked transmission cooler or low fluid levels, or internal slipping from worn clutches generating heat without transferring power effectively. Hot weather and stop-and-go traffic compound cooling challenges, while aggressive driving with frequent high-RPM launches stresses cooling systems. Install auxiliary transmission coolers for vehicles regularly towing or operating in demanding conditions, and ensure cooling system cleanliness and proper fluid levels.

Primary overheating causes:

Modern transmissions typically last 150,000-200,000 miles with proper maintenance including regular fluid changes, prompt leak repairs, and gentle operation avoiding excessive slipping or overheating. Some transmissions exceed 300,000 miles when meticulously maintained, while neglected units fail before 100,000 miles from contaminated fluid damage. Driving habits dramatically impact longevity—smooth acceleration, avoiding excessive heat, and proper gear selection for conditions extend transmission life significantly beyond what harsh operation allows.

Longevity factors: