Phone:

(701)814-6992

Physical address:

6296 Donnelly Plaza

Ratkeville, Bahamas.

Is your Chevy Silverado feeling less like a dependable workhorse and more like a hesitant companion? That unsettling sensation of the engine revving without a corresponding surge of power is a classic sign of transmission slipping—a problem you should never ignore. This definitive guide delivers 5,000+ words of expert-driven insights, from simple DIY checks to complex repairs, empowering you to diagnose, address, and prevent transmission slipping in your Silverado for good. We’ll dive deeper than any generic article, providing model-specific details and actionable advice to save you time, money, and stress.

Getting a firm handle on what transmission slipping actually entails is your first line of defense. It’s more than just a minor annoyance; it’s a critical symptom that your truck’s power delivery system is compromised. By understanding the mechanics and recognizing the early warnings, you can take proactive steps before a simple fix turns into a financial nightmare.

Transmission slipping occurs when there’s a failure in the connection between the engine’s power and the transmission’s output to the wheels. Imagine pressing the accelerator but the power is being lost somewhere in between—that’s the core of the issue. It’s not a single problem but a symptom of several potential underlying failures, ranging from low fluid to severe internal damage.

Transmission slipping is the failure of the transmission to maintain a solid mechanical connection in a specific gear, leading to a loss of power transfer. The engine and wheels become momentarily out of sync. You’ll experience a sudden, unexpected change in engine RPM without a change in vehicle speed, often accompanied by a feeling of the truck “falling out of gear.”

Your Silverado has its own personality, and so do its problems. The signs of slipping can manifest in ways specific to its robust build. A healthy Silverado should shift with firm, confident precision, whether it’s a city model or a heavy-duty hauler. When it’s not, you’ll notice distinct irregularities that are hard to miss.

Catching slipping in its infancy is the ultimate money-saving skill. The early signs are often subtle but become obvious if you’re paying attention. Don’t wait for a complete failure; integrate these simple checks into your regular driving routine to spot trouble long before it escalates.

The world of auto repair is full of well-intentioned but dangerous misinformation. Believing in these common myths can lead you to delay necessary repairs or attempt fixes that cause more harm than good. Let’s debunk three of the most pervasive myths right now.

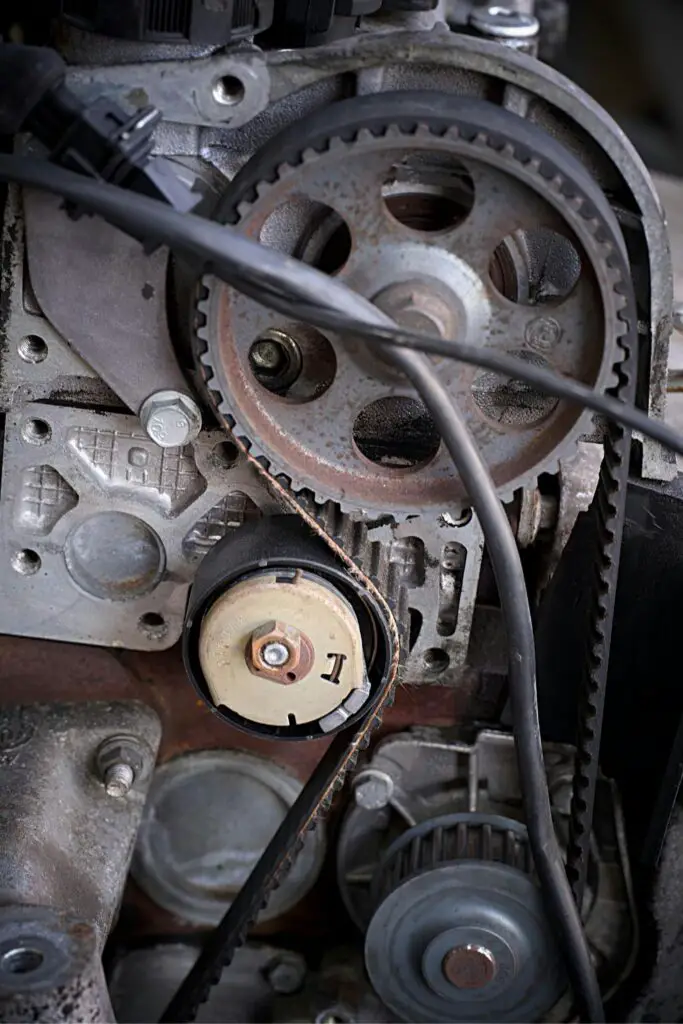

To truly diagnose a problem, you need a basic understanding of the system. The transmission is the heart of your Silverado’s drivetrain, a complex orchestra of mechanical, hydraulic, and electronic components working in perfect harmony. When one instrument is out of tune, the entire performance suffers.

Most modern Silverado’s use sophisticated automatic transmissions, but understanding the difference helps clarify the slipping concept. An automatic transmission uses a hydraulic system and a torque converter to change gears seamlessly, while a manual relies on the driver to operate a clutch and shift lever. Slipping in a manual often points directly to a worn clutch, whereas in an automatic, the causes are more varied.

Your Silverado’s transmission is a marvel of engineering, comprised of several critical parts. Knowing their names and functions demystifies the repair process and helps you communicate effectively with mechanics. Each component has a specific role, and the failure of any one can lead to slipping.

Transmission fluid is the lifeblood of your Silverado’s automatic transmission. It’s a multi-tasking marvel that goes far beyond simple lubrication. Using the wrong fluid or letting it get dirty or low is one of the fastest ways to induce slipping and cause catastrophic damage.

A 2005 Silverado and a 2023 Silverado are both fantastic trucks, but their transmissions are worlds apart. Older models rely more on robust hydraulic mechanics, while newer models are governed by sophisticated computers. This evolution changes the diagnosis process significantly.

Pinpointing the exact cause of transmission slipping is 90% of the battle. The issues can be broadly categorized into three areas: fluid problems, mechanical wear, and electronic glitches. By methodically investigating each category, you can zero in on the culprit without wasting money on unnecessary parts.

This is the most common and often the most easily fixable cause of transmission slipping. Think of transmission fluid as the essential communicator and protector within the system. When its quantity or quality is compromised, the entire operation falls apart.

Low fluid level is the number one cause of transmission slipping. Without enough fluid, the hydraulic system can’t build sufficient pressure to keep the clutch packs firmly engaged, causing them to slip and burn out. A leak is almost always the reason for low fluid.

Transmission fluid is designed to handle heat and friction, but over time, it breaks down. The clutch material and metal wear from normal operation create debris that contaminates the fluid. This dirty, burnt fluid loses its lubricating and hydraulic properties, leading to sluggish performance and slipping.

Not all transmission fluids are created equal. Using the incorrect fluid, even if it’s a high-quality brand, can lead to immediate slipping and long-term damage. Each transmission model is engineered to work with a specific fluid formulation (like Dexron VI for many GM models).

Checking your transmission fluid is a simple 5-minute task that can save you thousands. It’s the single most important piece of preventative maintenance you can perform. Doing it correctly, however, is crucial, as an inaccurate reading is worse than no reading at all.

When fluid issues are ruled out, the investigation turns inward to the mechanical components. These are the physical parts that endure immense pressure and friction every time you drive. Wear and tear is inevitable, but premature failure often points to a lack of maintenance or pre-existing conditions.

Inside your automatic transmission are stacks of alternating steel and friction discs called clutch packs. These are responsible for locking planetary gearsets to create each gear. Over time, the friction material wears down, just like a brake pad, losing its grip and causing slipping, especially under load.

The torque converter is the coupling between your engine and transmission. Inside, a stator and a complex arrangement of fins manage fluid coupling and multiplication. If its internal clutch fails or its fins become damaged, it cannot efficiently transfer power, leading to a sensation of slipping, especially from a stop.

In some older Silverado transmissions, bands are used to hold certain components stationary to achieve different gear ratios. A band is a steel strap with a friction lining. If it wears out, becomes glazed, or its adjustment loosens, it cannot hold effectively, causing a sharp, jerking slip.

The valve body is a maze of channels and valves that direct hydraulic fluid to the appropriate clutch packs and bands. If a valve sticks due to debris or wear, or if a spring loses its tension, the fluid pressure can be misdirected, causing delayed shifts, harsh shifts, or slipping.

Modern Silverados are rolling computers, and their transmissions are no exception. What feels like a mechanical slip can often be traced back to an electrical sensor sending bad data or a software bug issuing a faulty command. Diagnosing these issues requires a different toolkit and a logical approach.

Solenoids are electro-hydraulic valves that control the flow of fluid in the transmission based on commands from the TCM. Sensors, like the Transmission Fluid Temperature (TFT) and Input/output Speed Sensors, provide critical data. A failure in any of these can cause erratic shifting and slipping.

The TCM is the transmission’s dedicated computer. It processes data from all sensors and commands the solenoids to shift. If the TCM itself develops an internal fault, has corrupted memory, or loses power, its shifting commands become unpredictable, mimicking mechanical slipping.

The nervous system connecting the TCM, sensors, and solenoids is a complex wiring harness. A single chafed wire, a corroded connector, or a poor ground can interrupt signals or provide incorrect voltage, leading to intermittent and frustrating slipping issues that are hard to diagnose.

Automakers continuously release updated software (reflashing) for the TCM to address known shifting issues, improve fuel economy, and enhance durability. A simple software update at your dealership can sometimes resolve a slipping complaint without any physical repairs.

Before you spend a single dollar on parts, a thorough diagnosis is essential. A methodical approach, starting with the simplest and cheapest checks, will lead you to the root cause efficiently. Throwing parts at a transmission problem is an expensive and often ineffective strategy.

You don’t need to be a master technician to perform a preliminary investigation. Your own senses and one or two inexpensive tools can provide a wealth of information and point you firmly in the right direction, saving you a costly diagnostic fee at a repair shop.

Your built-in sensors—your eyes, ears, and nose—are your first and best diagnostic tools. Pay close attention to the specific circumstances under which the slipping occurs. This contextual information is invaluable for you or your mechanic.

An OBD-II (On-Board Diagnostics) scanner is a critical tool for any modern vehicle owner. It plugs into a port under your dashboard and reads fault codes stored by the truck’s computers. For transmission issues, you need a scanner that can read both powertrain and transmission-specific codes.

The truck’s computer is constantly running self-checks. When it detects a problem, it stores a Diagnostic Trouble Code (DTC). While a code doesn’t tell you exactly which part to replace, it gives you a powerful clue about which system to investigate.

Finding a puddle of red fluid under your truck is a clear sign, but sometimes leaks are small and hard to spot. A systematic approach will help you find the source quickly, so you can determine if it’s a simple fix or a sign of something more serious.

When your initial checks point to a complex internal issue, or if the problem is intermittent and elusive, it’s time to call in the professionals. A reputable transmission shop has the expertise and specialized equipment to diagnose problems that are impossible to find in a home garage.

Knowing when to hand over the reins to a professional is a sign of a smart DIYer. If you’ve checked the fluid and scanned for codes but the problem persists, or if the symptoms suggest severe internal damage, stopping your investigation can prevent further harm.

The cost of a professional diagnosis is an investment, not an expense. It prevents you from paying for repairs you don’t need. Most reputable transmission specialists will charge a fee to perform a thorough inspection, which often includes a road test, electronic scan, and physical pressure tests.

Don’t wait for a failure to have your transmission looked at. If you own a high-mileage Silverado or use it for heavy towing, a periodic professional check-up can identify small issues—like slight pressure drops or early solenoid wear—before they lead to a catastrophic failure.

The transmission is often blamed for problems that originate elsewhere. A skilled mechanic knows to check related systems before condemning the transmission. Insist on a thorough diagnosis and ask for an explanation of how they ruled out other potential causes.

Now for the actionable part. The fixes for transmission slipping range from simple top-offs that cost a few dollars to major surgeries that run into the thousands. The correct path depends entirely on the outcome of your diagnosis. Let’s break down the solutions from the simplest to the most complex.

These are the solutions you should always try first. They address the most common causes of slipping and require minimal mechanical skill and investment. Successfully fixing your truck with one of these methods is incredibly satisfying and cost-effective.

If your fluid level is low, topping it off might be the instant cure. If the fluid is dark, discolored, or smells burnt, a full fluid and filter change is necessary. This is the single most impactful maintenance task you can perform for transmission health.

This fix only applies to certain older transmission models (like the 4L60E) that have externally adjustable bands. It’s a simple procedure that involves loosening a lock nut and turning an adjustment screw a specific number of turns to retain the band.

If diagnostic codes point to a specific shift solenoid, it can often be accessed by dropping the transmission pan. Sometimes, the solenoid is just gummed up with debris and can be cleaned with a specialized solvent. If cleaning doesn’t work, replacement is the next step.

The TCM has an adaptive memory that “learns” your driving habits to optimize shift quality. If you’ve replaced a component or the shifting has become erratic, resetting this adaptive memory can often restore smooth operation. It’s a free and non-invasive procedure.

When the quick fixes don’t solve the problem, the issue is likely internal and requires significant mechanical skill, special tools, and a clean working environment. These jobs are best left to experienced DIYers or professional transmission technicians.

Replacing a torque converter is a major job, but it’s less invasive than a full transmission rebuild. The transmission must be removed from the truck to access and replace the converter, which is bolted to the engine’s flexplate. This is the solution for shuddering and converter clutch-related slipping.

An overhaul involves disassembling the transmission to replace the worn clutch packs, seals, and other soft parts. This is the definitive fix for slipping caused by burnt or glazed clutches. It requires a high level of expertise, a spotless work area, and a detailed understanding of transmission assembly.

A faulty valve body can sometimes be repaired without a full transmission removal. In some cases, a “valve body kit” is available, which includes new solenoids, a separator plate gasket, and corrective sleeves for worn bores. This can resolve pressure-related slipping and shifting issues.

There comes a point when repair is no longer economically viable. If multiple internal components are damaged—such as the planetary gearsets, pump, and clutch packs—the cost of an overhaul may approach or exceed the cost of a replacement unit. This is the nuclear option, but sometimes it’s the most practical one.

An ounce of prevention is worth a pound of cure, and nowhere is this truer than with your Silverado’s transmission. Consistent, proactive care is the key to achieving the legendary longevity these trucks are known for. Implement these habits to keep your transmission running smoothly for years and hundreds of thousands of miles.

Sticking to a disciplined maintenance schedule is the single most important thing you can do for your transmission. It’s not glamorous, but it is overwhelmingly effective. Treat your transmission well, and it will return the favor with reliable service.

Transmission fluid degrades over time due to heat, friction, and oxidation. Changing it at regular intervals flushes out contaminants and restores its protective properties. Ignoring this is the primary cause of premature transmission failure. Don’t fall for the “lifetime fluid” myth.

A visual inspection of external components during an oil change can catch small problems before they become big ones. Look for signs of wear, leaks, or damage on parts that are easy to see and reach. This takes only a few minutes but can provide early warning.

Heat is the enemy of your transmission. Excessive temperatures break down fluid and cook clutch materials. For trucks used for towing or performance, installing an aftermarket transmission temperature gauge is one of the best investments you can make.

How you drive has a direct impact on how long your transmission lasts. Aggressive driving creates extreme heat and shock loads that drastically shorten its life. Adopting smoother habits is a free and easy way to ensure longevity.

For newer Silverados, transmission health isn’t just about mechanics; it’s about digital intelligence. Keeping the transmission’s software current is as important as changing its fluid. These updates provide refinements that can resolve bugs and improve the overall driving experience.

Software updates are not just for adding new features; they are crucial for reliability and performance. Manufacturers release updates to fix known issues with shift quality, torque converter clutch engagement, and overall calibration that can manifest as slipping or shuddering.

General Motors issues Technical Service Bulletins (TSBs) that often describe specific shifting complaints and provide the software update as the solution. Being aware of these can help you ask your dealer the right questions.

The only reliable source for official TCM software updates is your local Chevrolet/GMC dealership. Their diagnostic computers are connected directly to GM’s technical database and can identify and apply all available updates for your truck’s specific VIN.

The world of aftermarket performance tuning is tempting, but it carries risks. Aggressive “performance” transmission tunes often increase line pressure and shift firmness to the point of causing premature wear, harsh engagement, and even component failure.

The cost of repair is the biggest concern for most owners, and it varies wildly based on the root cause and who does the work. Getting a clear picture of potential expenses helps you budget and avoid being overcharged.

Average Costs for Common Repairs

Transmission repair costs are not one-size-fits-all. A simple fluid service is relatively inexpensive, while internal repairs are a significant investment. The following table breaks down realistic price ranges for common fixes.

DIY Repairs vs. Professional Services

The choice between DIY and professional repair depends on your skill level, available tools, and the complexity of the job. Weigh the initial savings of DIY against the time, risk, and potential for error.

DIY is best for: Fluid changes, external leak fixes, solenoid replacement (if accessible), and band adjustments.

Professional is best for: Internal work, computer diagnostics, pressure testing, and full rebuilds.

Warranty Consideration: Professional work almost always comes with a parts and labor warranty.

A valid warranty can reduce your out-of-pocket cost to zero, but it’s crucial to understand the terms. Warranties have specific conditions, and coverage can be voided by improper maintenance or modifications.

New Vehicle Warranty: Typically covers the transmission for 5 years/60,000 miles.

Powertrain Warranty: Often extends to 10 years/100,000 miles on certified pre-owned models.

Aftermarket Warranty: Provided by third-party companies; read the fine print carefully for exclusions.

Factors Influencing Overall Repair Expenses

The final bill is influenced by more than just the broken part. Labor rates, the truck’s model year, and regional differences all play a significant role in the total cost.

Labor Rates: Dealerships charge more per hour than independent shops.

Transmission Model: A 10-speed transmission is more complex and expensive to rebuild than a 4-speed.

Vehicle Location: Labor and part costs are higher in major metropolitan areas.

This is a dangerous game to play. Driving with a slipping transmission is like driving with a ticking time bomb. The duration you can “get away with it” depends on the cause, but the risk of causing catastrophic, secondary damage is always high.

Risks of Ignoring Slipping Issues

Ignoring a slip doesn’t make it go away; it makes it worse. What starts as a minor issue with a single component can quickly escalate into a failure that damages the entire transmission system, multiplying the repair cost.

Burned Clutches: Slipping creates intense friction and heat, which glazes and destroys clutch friction material.

Metal Contamination: Worn clutches and bands contaminate the fluid with debris that circulates and damages other parts.

Overheating: Slipping causes the fluid to overheat, breaking it down and losing its lubricating properties.

Immediate Consequences for Other Vehicle Parts

A failing transmission doesn’t exist in a vacuum. The problems can spread to other expensive components, turning a single repair into a cascade of failures that can leave your truck completely undrivable.

Damage to the Torque Converter: Debris from slipping clutches can be pumped into and destroy the torque converter.

Clogged Cooler and Lines: Contaminated fluid can clog the external transmission cooler and lines.

Strain on the Engine: The engine may be forced to run at abnormally high RPMs, causing undue stress.

Signs It’s Time to Stop Driving

If you notice any of the following symptoms, you should stop driving the vehicle immediately and have it towed to a repair facility. Continuing to drive could be unsafe and will certainly lead to a much more expensive repair.

The transmission is slipping violently or consistently in every gear.

You see smoke coming from the transmission or smell something burning strongly.

The car will not move forward or reverse or moves very slowly with high engine RPM.

Tips for Safe Emergency Driving

If you must drive the vehicle a very short distance to get off a busy road or to a nearby shop, you can minimize the damage by following these precautions. This is for emergency use only.

Drive as slowly and gently as possible, avoiding any sudden acceleration.

Keep the journey extremely short— less than a mile or two is ideal.

Manually select a lower gear (like 2 or L) to prevent the transmission from shifting and potentially slipping.

Whether or not your repair is covered depends entirely on the specific wording of your warranty agreement and the root cause of the failure. Proper documentation and maintenance are your best allies in getting a claim approved.

Coverage for New Silverado Models

If your Silverado is new or certified pre-owned (CPO), you have a strong chance of coverage. Warranties are designed to cover defects in materials and workmanship, which includes internal transmission components.

Bumper-to-Bumper: Covers almost everything for 3 years/36,000 miles, including transmission issues.

Powertrain Warranty: Covers the engine, transmission, and driveline for a longer period, typically 5 years/60,000 miles or more.

CPO Warranty: Extends the powertrain coverage on qualifying used vehicles, often up to 10 years/100,000 miles from the original in-service date.

Conditions and Exclusions in Warranty Agreements

The warranty is not a blanket coverage policy. Manufacturers can deny a claim if they can prove the failure was due to owner neglect, abuse, or unauthorized modifications rather than a manufacturing defect.

Lack of Maintenance: The most common reason for denial. If you cannot prove you changed the fluid, the claim may be rejected.

Abuse or Misuse: Evidence of racing, heavy towing beyond capacity, or fluid contamination can void coverage.

Aftermarket Modifications: A performance tune or non-OEM parts can be used to deny a claim.

Importance of Documenting Repairs

Your service records are your evidence in a warranty dispute. A well-documented maintenance history proves that you have taken proper care of the vehicle, making it very difficult for the manufacturer to claim neglect.

Keep all receipts for fluid, filters, and any related services.

Use a logbook or digital app to record the date, mileage, and service performed.

Have major services performed by a reputable shop that provides detailed invoices.

Approach a warranty claim calmly and prepared. Being organized and professional will greatly increase your chances of a smooth and successful experience. You are more likely to get a positive outcome if you are a well-informed and reasonable customer.

Contact your dealership’s service advisor first and explain the problem clearly.

Bring all your maintenance records with you to the appointment.

If the claim is initially denied, politely ask for the denial in writing with a specific explanation, and don’t be afraid to escalate to GM corporate if necessary.

Final Thought

Transmission slipping in your Silverado is a serious issue, but it is not a hopeless one. By understanding the causes—from simple fluid leaks to complex electrical faults—you are empowered to take the right action. Remember, the ultimate fix begins with prompt diagnosis and is sustained by diligent, regular maintenance. Don’t let a minor slip turn into a major financial setback. Take control of your truck’s health today by checking your fluid, monitoring its behavior, and addressing any concerns immediately. Your Silverado is built to last; with the right care, its transmission will be no exception.